At Stout Industrial Technology, we’re not just revolutionizing agriculture; we’re redefining it. With our cutting-edge True Vision technology and a relentless commitment to innovation, we’re making strides in AI and robotics that are changing the way growers operate. Today, I’d like to share insights into our journey, our capabilities, and what’s in store for the future.

True Vision is at the heart of what sets Stout apart. It is a sophisticated system combining AI and machine vision to detect and classify objects in real-world, ever-changing environments. Unlike traditional systems that require structured settings, True Vision excels in challenging outdoor conditions, utilizing advanced software, AI, and robust camera hardware to meet the field conditions.

True Vision operates using a convolutional neural network that identifies and classifies crops and weeds. This is further enhanced through a proprietary tracking algorithm. True Vision communicates detailed position information to an implement controller, enabling machines to perform precise agricultural tasks, setting a new standard for efficiency and accuracy in farming.

The journey of True Vision began with Jeff Antle’s vision to automate the weeding and cultivating process under high weed pressure. Existing machine vision technologies, like blob detection, were insufficient for real farming conditions. Recognizing that recent advances in AI were instrumental in solving this problem, Jeff started to assemble the team to lay the groundwork for what Stout True Vision is today – a high performance field-ready AI machine vision system.

Developing True Vision was not without its hurdles. One of the biggest challenges was the need for extensive datasets to train the AI models. To address this, we built portable data collection systems that enabled us to gather images and farm data from a multitude of crops in various regions and field conditions. Stout’s fleet of data collectors allowed us to train new AI models quickly and efficiently. This ability to rapidly adapt to new applications is a significant differentiator for Stout.

Looking ahead, True Vision continues to evolve. We have recently added capabilities for plant size and spacing histograms, heat maps, and web applications for real-time monitoring and detailed analysis of how crops are growing. Future enhancements are in the works to improve and enhance data feeds and provide growers more insights on how to improve their farming practices.

Our robotics and AI team is dedicated to continuous improvement. We focus on expanding our AI models to include new crop varieties and weeds, enhancing weed detection, and adding new functionalities to our Smart Cultivator. Our goal is to stay at the forefront of innovation, ensuring our customers always have access to the most advanced precision farming products.

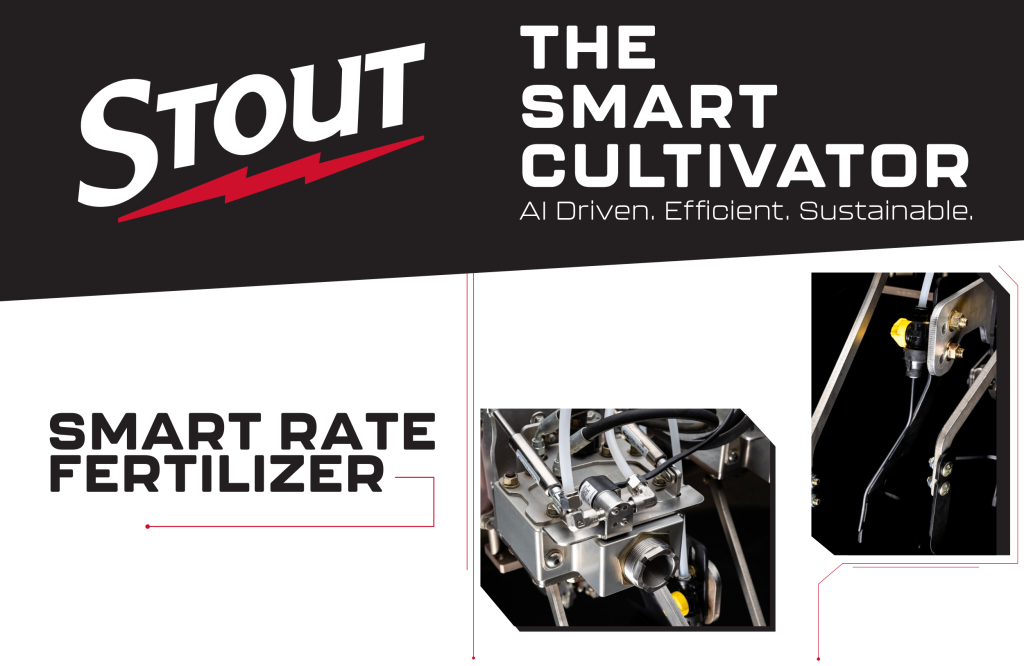

Stout recently unveiled Smart Rate Fertilizer (SRF), an add-on for the Smart Cultivator and the world’s first plant-specific variable rate fertilizer system. Traditional variable rate application systems apply different rates of fertilizer to each part of the field, whereas SRF uses Stout True Vision to apply the right dose to each individual plant. By giving plants just the right amount of fertilizer, SRF lowers costs and reduces fertilizer runoff.

We have several exciting projects in the pipeline beyond the Smart Cultivator and Smart Rate Fertilizer. While details are under wraps, rest assured that our team is working on groundbreaking technologies that will further enhance our capabilities and the impact on the agriculture industry.

One of the key strengths of True Vision is its user-friendliness. It is designed to be self-tuning and adaptive, ensuring that operators do not need to be engineers to use it effectively. We’ve tested our interfaces extensively with customers, resulting in intuitive solutions like a mobile app for in-cab monitoring, which allows operators to manage the system without leaving their tractors.

Continued feedback from growers is invaluable. Our products are designed to solve real problems and improve margins for our customers. By working closely with growers, we ensure that our solutions are practical, effective, and aligned with their needs. This collaborative approach helps us focus our efforts on the most impactful areas.

As we remain at the cutting edge, we continuously experiment with new technologies and stay active in industry conferences. Partnerships, such as with industry leader Tanimura & Antle, provide us with opportunities to test new ideas and receive immediate feedback, keeping us ahead of industry trends.

Our robotics team is highly interdisciplinary, comprising machine learning / AI experts, mechanical engineers, controls engineers, and other specialists. We work closely with other departments to develop, test, and refine new technologies. This collaborative process ensures that our innovations are practical and ready for production.

The future of robotics in agriculture is incredibly exciting. We are at the beginning of a wave of robotic solutions that will make farming more productive and efficient, while reducing environmental impacts. Stout is building the tools to enable precise, plant-level decision-making, which is key to revolutionizing farming practices. By applying science at the individual plant level, we open doors to unparalleled advancements in agriculture.

These insights underscore Stout’s commitment to innovation and excellence in AgTech. With True Vision technology, we are not just keeping pace with industry trends; we are setting them. As we continue to evolve and expand our capabilities, we remain dedicated to providing growers with the tools they need to thrive in a rapidly changing world. Stay tuned for more exciting developments from Stout Industrial Technology!

About Steven Snyder: Steven co-founded Stout Industrial Technology and is the Director of Robotics, leveraging his expertise to bridge the gap between traditional industry and Silicon Valley innovations. With a rich background in autonomous robotics, electro-optics, automotive and aerospace, he has held key positions at Motivo Engineering and Applied Minds, where he designed complex systems and led significant technological advancements. Steven’s early career at GeneFluidics saw him develop critical software and hardware for medical research, showcasing his multifaceted engineering skills. He holds a degree in Cybernetics from UCLA, a multidisciplinary program with studies in computer science, electrical engineering, statistics, systems biology, and chemistry.

About Stout Industrial Technology: A Salinas, CA based artificial intelligence Company focusing on labor-intensive applications in agriculture. The Company builds software-defined implements for tractors that use machine vision and AI to identify and remove weeds via mechanical actuation instead of chemicals. Born inside a grower-shipper operation, Stout’s hardware and software solutions are developed from the grower’s perspective, hardened in the field prior to commercialization and continuously improved to help growers lower their operating costs and increase their margins.

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”