Navigating Ag Tech: A Journey of Adaptation and Innovation

My journey into ag tech wasn’t exactly planned, but looking back, it makes perfect sense. Early in my career, I worked in operations where everything was done the old-school way—by hand, on paper, with little to no technology involved. Scheduling, field applications, fertilizer dispatch—all of it was manual. But then I got my first taste of technology in the industry. I saw what GPS monitoring and other digital tools could do, and it changed my perspective. It became clear that there was a huge opportunity to modernize these outdated processes. I realized that not only could technology make agriculture more efficient, but it could also open doors to new possibilities that hadn’t even been considered yet. That curiosity led me down the path I’m on today.

Agriculture is unpredictable. Weather, labor availability, and market fluctuations all impact day-to-day operations. As Director of Sales Operations, I’ve had to learn how to balance structured planning with the flexibility to pivot at a moment’s notice. This industry demands both—a clear vision of where you’re headed, but also the ability to react quickly when things don’t go as planned. It’s a leadership style that embraces adaptability while staying grounded in long-term goals.

One of the toughest parts of my role is navigating the natural resistance to change within agriculture. At the end of the day, this industry is about production—getting from seed to harvest as efficiently as possible. Introducing new technology, no matter how beneficial, can be seen as a disruption. Growers need to know that integrating something new won’t just be an extra step—it has to improve efficiency without negatively impacting their bottom line.

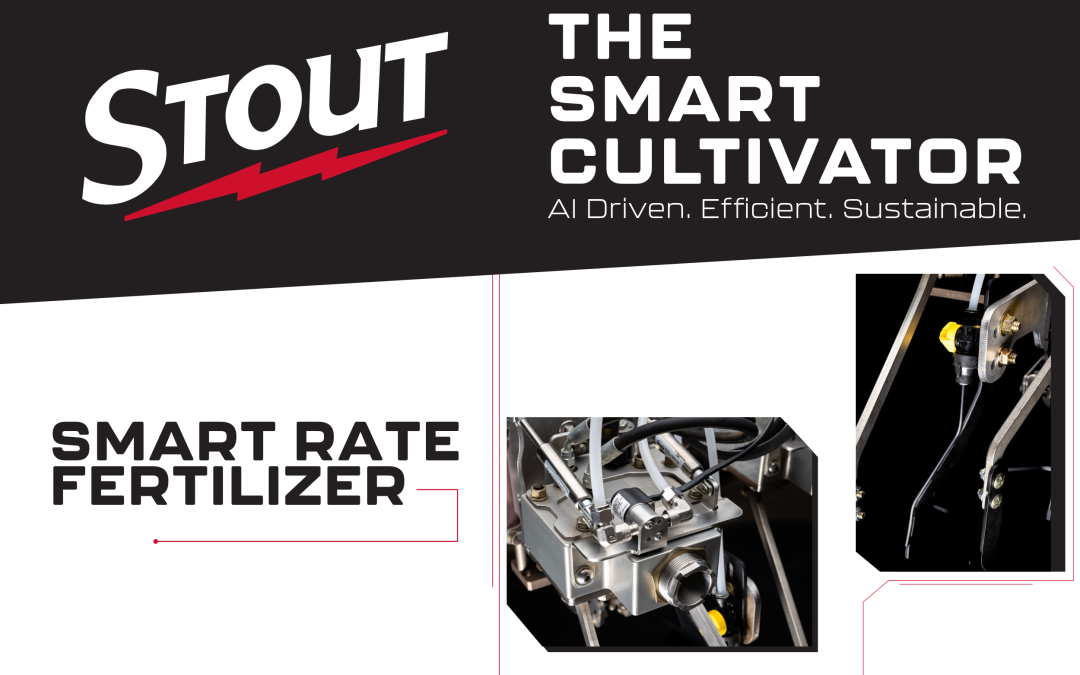

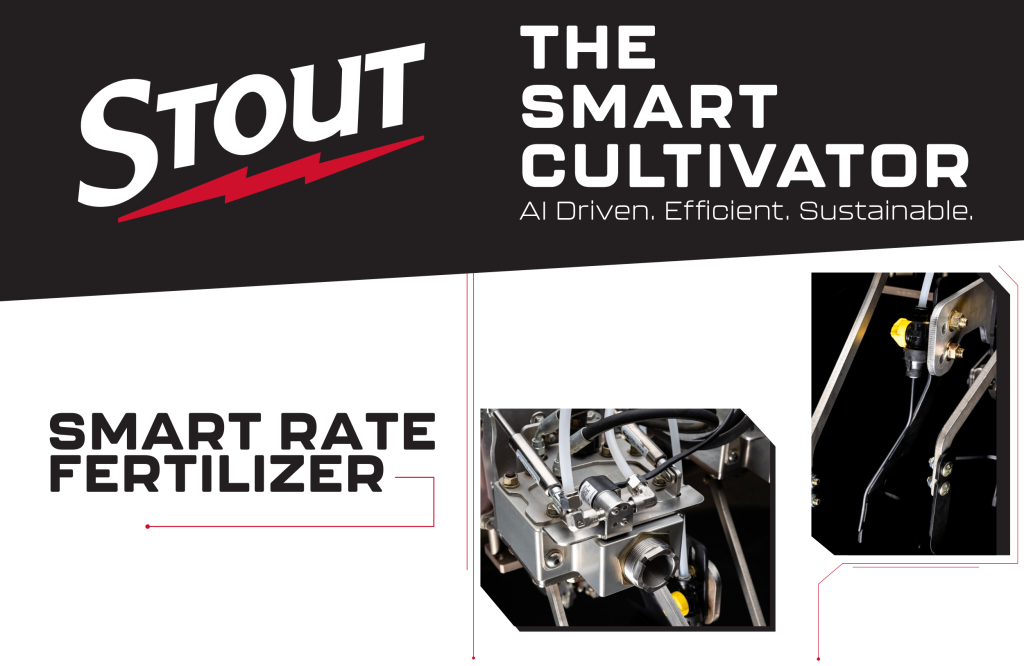

The biggest challenge isn’t just selling a piece of equipment—it’s shifting mindsets. Many farming practices have been done a certain way for generations, and now we’re asking people to trust a machine to do the work that’s historically been done by hand. That’s a big leap. To overcome this, we focus on proving the real-world benefits of the Stout Smart Cultivator—how it reduces labor challenges, provides immediate data for decision-making, and ultimately helps growers improve their operations.

Technology is touching every part of agriculture—from the field to the packing sheds to the sales office. At Stout, our focus is on using data-driven solutions to help growers make better, real-time decisions. Instead of reacting to issues after they’ve already impacted a crop, our goal is to provide insights that allow growers to adjust before it’s too late. That’s where the future of ag tech is headed: proactive, not reactive.

Innovation isn’t always easy, and pushing boundaries comes with its challenges. But what keeps our team motivated is the fact that we’re doing something new. We’re at the forefront of a movement that’s changing the way farming operates. There are days when things don’t go as planned, when frustrations run high, but in those moments, we remind ourselves why we’re here.

The ag tech space is full of exciting developments, but not all technology is useful today. Some innovations look great on paper but aren’t ready for practical application. Our job is to refine what we offer and ensure that it truly benefits the people who use it. That means listening to growers, understanding their needs, and adapting our solutions accordingly. It’s not about pushing technology—it’s about creating solutions that make sense in the real world.

If I had to pick one skill that’s essential for success in this space, it would be understanding growers. You need real-world experience to truly grasp what they’re up against—the pressures, the regulations, and the challenges they face every day. Without that understanding, it’s difficult to communicate how technology can help. The key isn’t telling them what they need—it’s listening to what they actually need and working with them to find the best solution.

Over the next five to ten years, I think we’ll see the true potential of ag tech start to unfold. Right now, there’s a lot of excitement, but not every new innovation will stand the test of time. The companies that stay focused, listen to their customers, and truly integrate into agriculture’s real-world challenges will be the ones that succeed. Adoption won’t happen overnight—it’s a gradual process. But as the technology matures and proves itself, we’ll see a shift toward more targeted, effective solutions that become essential tools for growers.

For me, that’s what makes this field so exciting. We’re not just creating technology for the sake of it—we’re solving real problems. And as long as we stay grounded in that mission, the impact we can make is limitless.

About Sal

Sal Espinoza is a dedicated leader in ag tech with a passion for innovation and problem-solving. With nearly a decade of experience in agriculture, he has held key roles at Wilbur-Ellis, FarmWise, and now Stout Industrial Technology, where he drives advancements in AI-powered automation for farming. Sal’s expertise lies in developing practical, grower-focused solutions that enhance efficiency, sustainability, and profitability in the field.

About Stout

Stout is at the forefront of agricultural innovation, specializing in precision implements and AI-driven solutions that enhance efficiency and productivity for growers. Committed to pushing the boundaries of agricultural technology, Stout continues to lead the way in developing advanced machinery for the farming community.